-

Customer-oriented innovation

With a dedicated 8-person R&D team averaging 10+ years of hands-on experience, we focus on practical, market-ready solutions. By closely collaborating with clients like Gucci,Louis Vuitton,Versace.we refine designs through iterative feedback—ensuring hangers meet real-world demands for durability, aesthetics, and cost-efficiency.

-

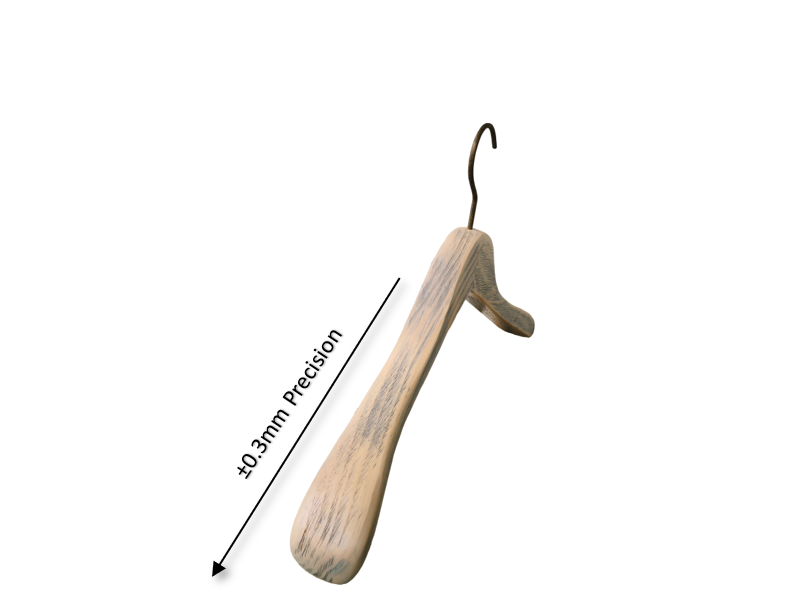

Scalable Solutions, Tailored For You

Leveraging 150+ adaptable molds and a monthly output of 200,000+ units, we balance agility with precision. Our streamlined process delivers prototypes in 7 days and bulk orders within 20 days, backed by rigorous material testing for moisture resistance and weight capacity.